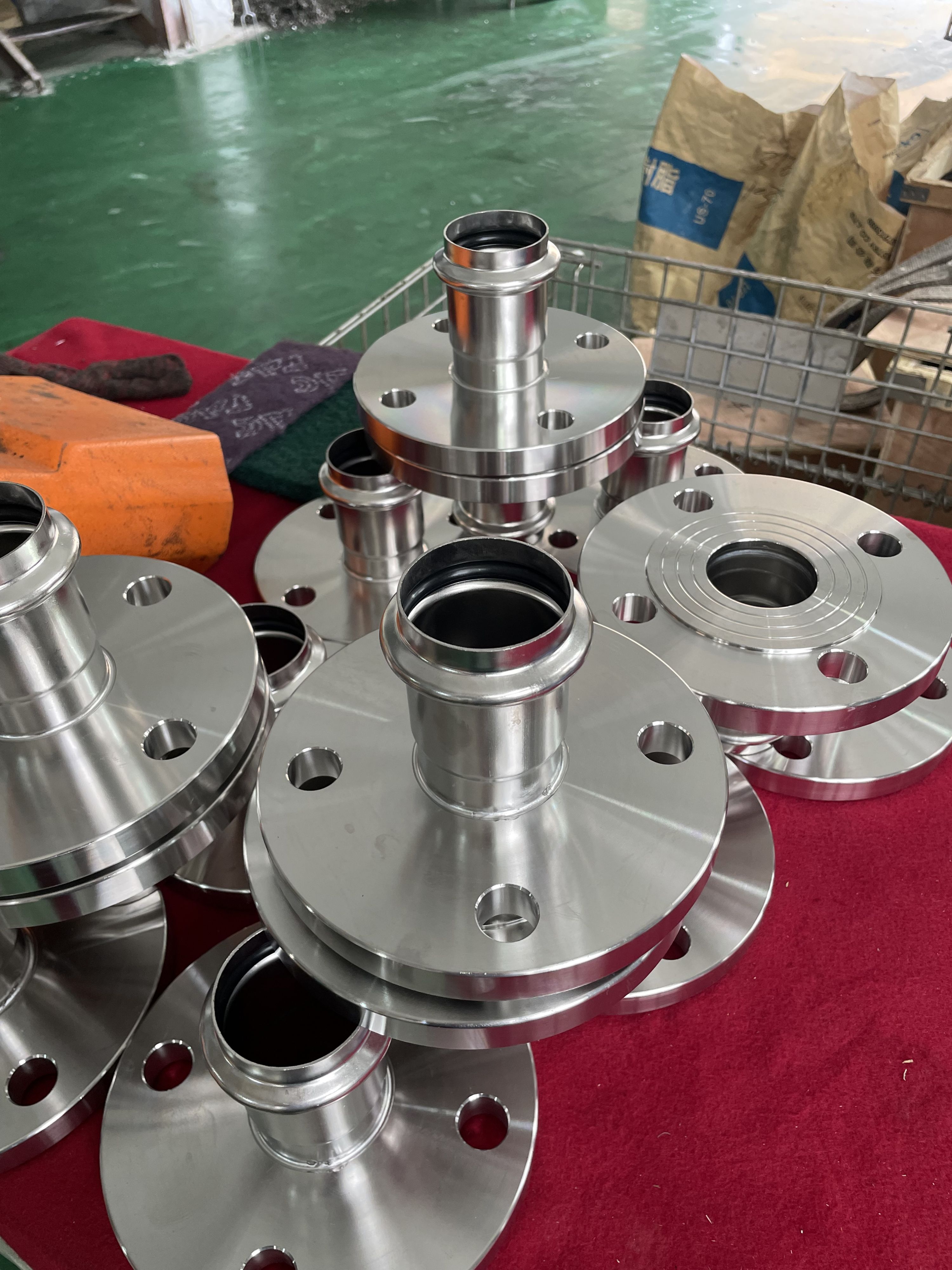

Compression/grooved flange fittings

This product is widely used in construction, hotels, and water companies

Products DETAILS

Compression/grooved flange fittings

These products are mainly used in construction, hotel engineering, clamp flanges, and groove flange fittings, which are important components in the field of pipeline connections. They each have a series of advantages and wide application areas.

###The advantages and applications of compression flanges

1. * * Connection reliability * *: The clamp type pipe fittings are sealed and fixed by using special tools to compress the pipe mouth, and have the characteristics of anti pulling and anti vibration.

2. * * Installation convenience * *: The installation process is simple, requires small operating space, and is maintenance free after installation.

3. * * Scope of application * *: Suitable for direct drinking water systems, tap water systems, heating systems, gas systems, etc., suitable for connecting drinking water, tap water, natural gas, household hot and cold water, medical gas, fire protection and other pipelines.

4. * * Material and Specification * *: Usually made of stainless steel 304/304L/316/316L, with a nominal pressure of ≤ 1.6MPa and a suitable temperature range of -20 ℃ to 110 ℃.

5. * * Mature technology * *: The S-shaped clamp type pipe fittings have a hexagonal cross-section crimping, which improves the anti rotation ability. The double clamp design provides two resistance rings, enhancing the pulling force.

###The advantages and applications of groove flanges

1. * * Fast installation speed * *: The installation speed of groove type pipe fittings is fast, without the need for welding and galvanizing and other subsequent work. The pipeline can be automatically centered and aligned through clamps.

2. * * Safety and reliability * *: Use a groove rolling machine and a hole opener to ensure the machining accuracy of the end groove. The sealing ring inside the clamp cavity achieves self tightening sealing, and the nominal pressure can reach up to 2.5MPa.

3. * * Easy Installation * *: With a small number of bolts and convenient operation, ordinary workers can start their work after simple training.

4. * * Economy * *: Will not damage the galvanized layer, reduce installation costs, shorten construction period, and create economic benefits in advance.

5. * * Environmental friendliness * *: No welding required, no welding slag pollution, no damage to the galvanized layer inside and outside the pipe, reducing noise and vibration transmission.

6. * * Easy maintenance * *: Pre assembly can be carried out first, and during maintenance, only the joints need to be removed for easy cleaning and replacement.

7. Scope of application: It can be used in various systems such as fire water systems, air conditioning hot and cold water systems, water supply systems, petrochemical pipeline systems, etc. It is suitable for connecting various types of pipes such as steel pipes, copper pipes, stainless steel pipes, etc.

The two types of flange fittings each have their own characteristics, and the selection needs to be based on specific engineering requirements and environmental conditions to determine which one to use.

###The advantages and applications of compression flanges

1. * * Connection reliability * *: The clamp type pipe fittings are sealed and fixed by using special tools to compress the pipe mouth, and have the characteristics of anti pulling and anti vibration.

2. * * Installation convenience * *: The installation process is simple, requires small operating space, and is maintenance free after installation.

3. * * Scope of application * *: Suitable for direct drinking water systems, tap water systems, heating systems, gas systems, etc., suitable for connecting drinking water, tap water, natural gas, household hot and cold water, medical gas, fire protection and other pipelines.

4. * * Material and Specification * *: Usually made of stainless steel 304/304L/316/316L, with a nominal pressure of ≤ 1.6MPa and a suitable temperature range of -20 ℃ to 110 ℃.

5. * * Mature technology * *: The S-shaped clamp type pipe fittings have a hexagonal cross-section crimping, which improves the anti rotation ability. The double clamp design provides two resistance rings, enhancing the pulling force.

###The advantages and applications of groove flanges

1. * * Fast installation speed * *: The installation speed of groove type pipe fittings is fast, without the need for welding and galvanizing and other subsequent work. The pipeline can be automatically centered and aligned through clamps.

2. * * Safety and reliability * *: Use a groove rolling machine and a hole opener to ensure the machining accuracy of the end groove. The sealing ring inside the clamp cavity achieves self tightening sealing, and the nominal pressure can reach up to 2.5MPa.

3. * * Easy Installation * *: With a small number of bolts and convenient operation, ordinary workers can start their work after simple training.

4. * * Economy * *: Will not damage the galvanized layer, reduce installation costs, shorten construction period, and create economic benefits in advance.

5. * * Environmental friendliness * *: No welding required, no welding slag pollution, no damage to the galvanized layer inside and outside the pipe, reducing noise and vibration transmission.

6. * * Easy maintenance * *: Pre assembly can be carried out first, and during maintenance, only the joints need to be removed for easy cleaning and replacement.

7. Scope of application: It can be used in various systems such as fire water systems, air conditioning hot and cold water systems, water supply systems, petrochemical pipeline systems, etc. It is suitable for connecting various types of pipes such as steel pipes, copper pipes, stainless steel pipes, etc.

The two types of flange fittings each have their own characteristics, and the selection needs to be based on specific engineering requirements and environmental conditions to determine which one to use.